Services We Provide

🔧 What Is Preventive Maintenance?

Preventive maintenance involves regular inspections and servicing to prevent potential failures before they occur. This approach is designed to:

✅ Reduce unexpected breakdowns and minimize costly repairs.

✅ Ensure continuous energy production without disruptions.

✅ Extend the lifespan of turbines, improving overall efficiency.

🔹 Preventive Maintenance Tasks

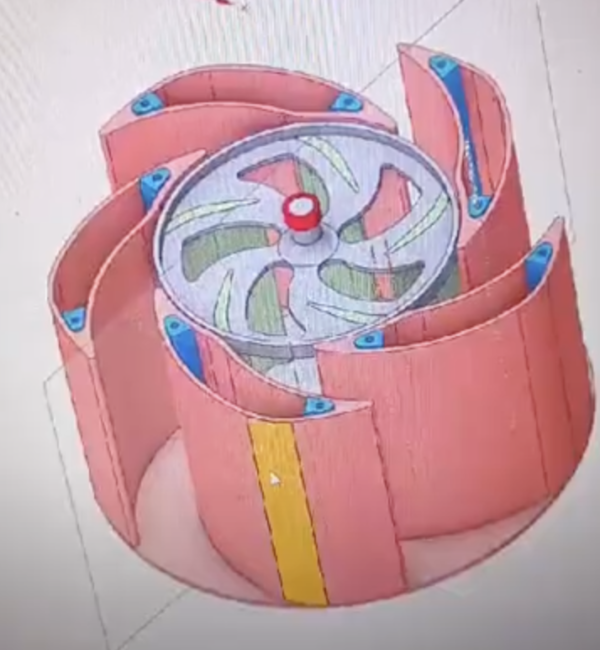

• Physical inspections of turbine blades, mounts, and electrical components.

• Lubrication of moving parts to reduce wear and friction.

• Software updates to improve AI-driven energy optimization.

• Cleaning and debris removal to maintain peak performance.

By implementing routine preventive maintenance, we ensure our turbines remain in top condition, avoiding costly repairs and ensuring consistent energy output.

📡 What Is Predictive Maintenance?

•Electrical output variations.

•Optimize energy production without disruption.

Implementing both preventive and predictive maintenance provides key advantages:

✅ Reduced Maintenance Costs – Fixing issues early is significantly cheaper than repairing a broken turbine.

✅ Higher Energy Output – A well-maintained turbine produces maximum energy without inefficiencies.

✅ Longer Equipment Lifespan – Regular maintenance extends the turbine’s durability, increasing ROI.

✅ Minimal Downtime – AI-driven alerts ensure maintenance occurs only when necessary, keeping the turbine running longer.

Milesell B.V., we combine preventive and predictive maintenance with AI-powered monitoring, setting a new standard for wind turbine reliability. Our approach ensures that businesses, municipalities, and homeowners enjoy uninterrupted clean energy with maximum efficiency and cost savings.

📞 Want to learn more about our smart wind turbine maintenance solutions? Contact us today!

Services We Offer

To keep your turbines operating at peak performance, we provide:

✅ Regular inspections to detect wear and tear.

✅ AI-driven predictive maintenance to prevent failures before they happen.

✅ Fast repairs and servicing to minimize downtime.

With our proactive maintenance approach, customers enjoy longer turbine lifespans and continuous energy savings.